Product appearance inspection based on the Chancepool vision software system is a method that uses computer vision technology to detect and identify objects in an automated manner by analyzing their shape, color, texture and other visual features. It is widely used in quality control, medical image analysis, safety monitoring, automation fields, etc. in the manufacturing industry. This technology uses image processing software and machine learning algorithms to achieve efficient and accurate detection, improving production efficiency, quality management and safety.

------------------------------------------------

Brand:ChancePool

Product Origin:China

Shipping Port:Shanghai

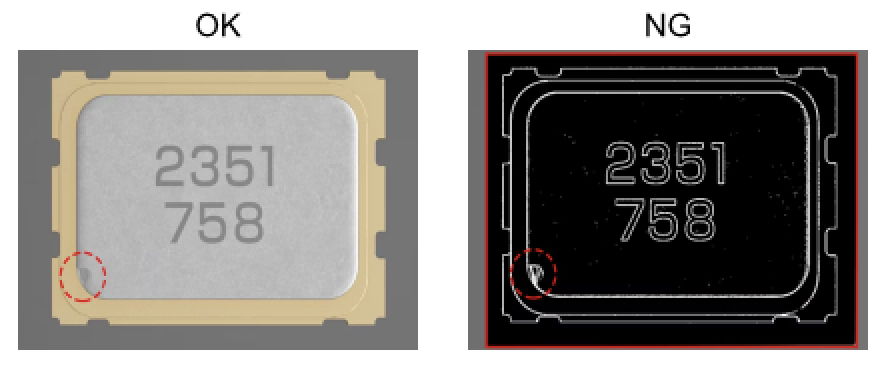

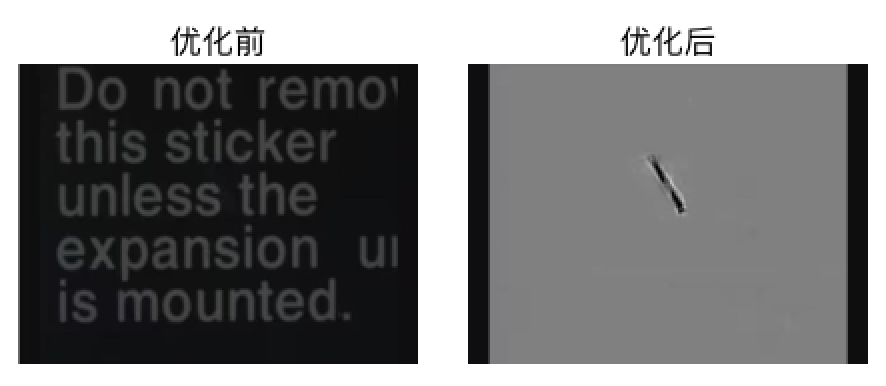

Detecting defects in crystal oscillators

When the color difference between the area to be detected and the background is not obvious, it is difficult to detect defects in the outline. Now, by partially illuminating the light source from four directions, the contour portion can be extracted, enabling stable detection.

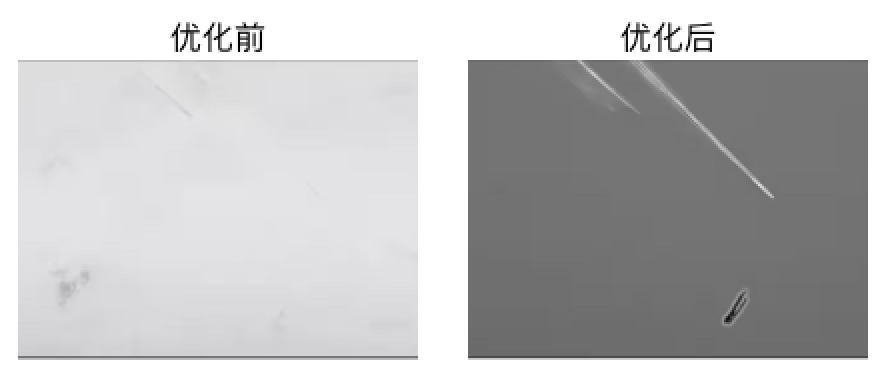

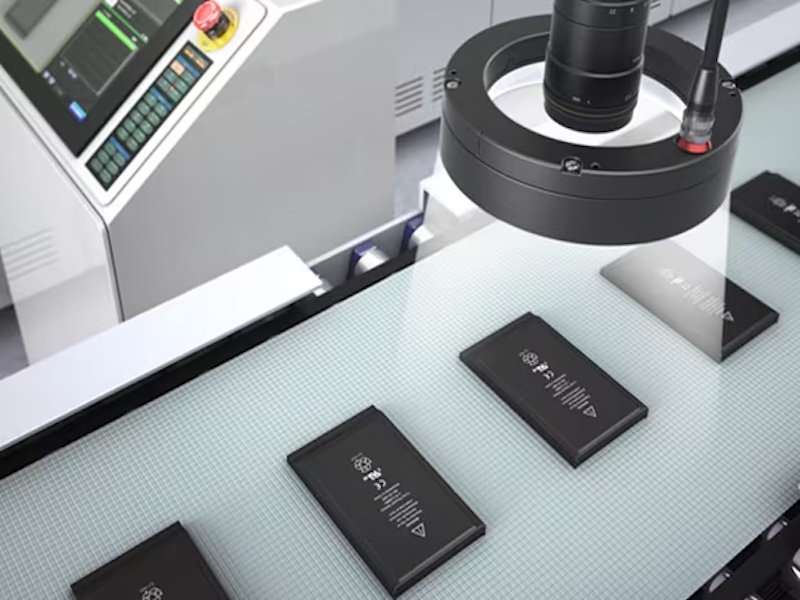

Check the appearance of the printed surface of the battery

It is difficult to distinguish printing and defects when performing appearance inspection on battery surface defects, dents, etc. Now, 2D information such as printing can be eliminated and only defects and dents can be detected.

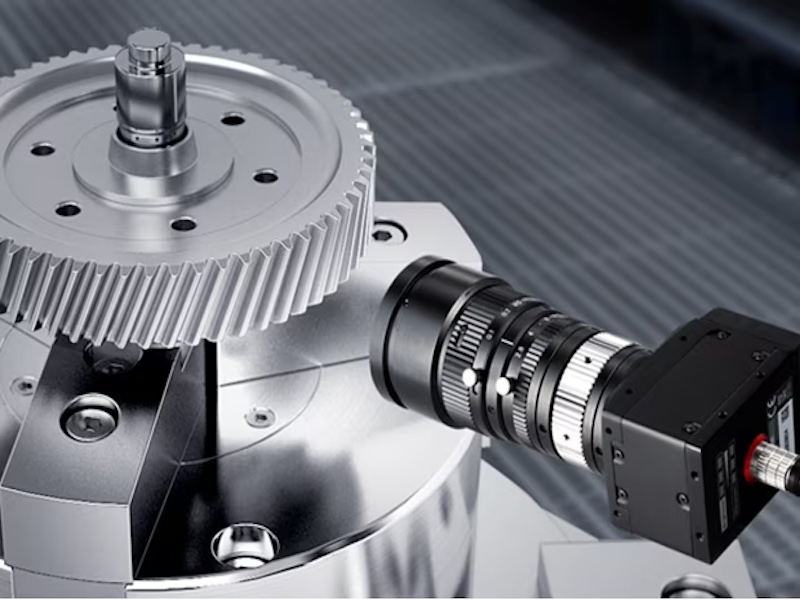

Gear appearance inspection

When detecting defects such as black scale residue, dirt, scratches, and dents on the side of cylindrical workpieces such as gears, it is difficult to illuminate the light uniformly. By using a line scan camera, cylindrical shapes can be photographed continuously. In addition, by using the specular reflection mode, appearance defects such as scratches, dents, and dirt can be detected with just one shot.

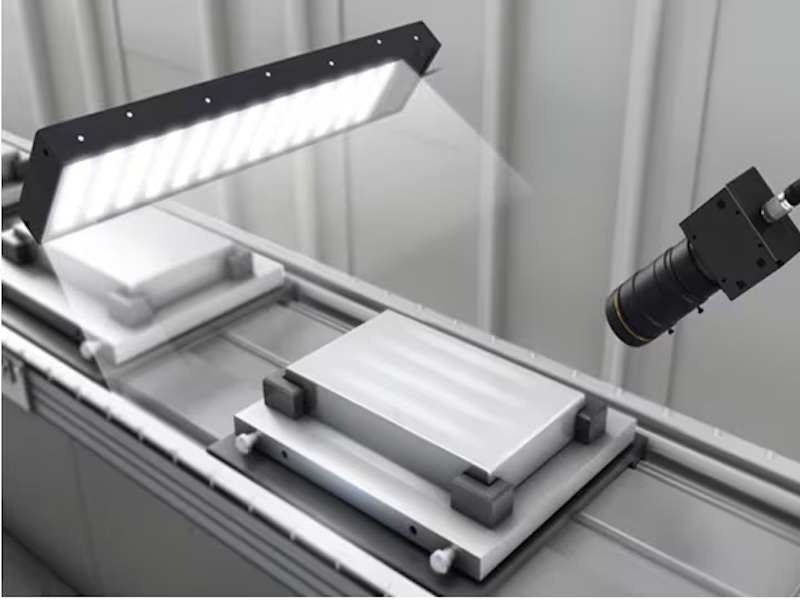

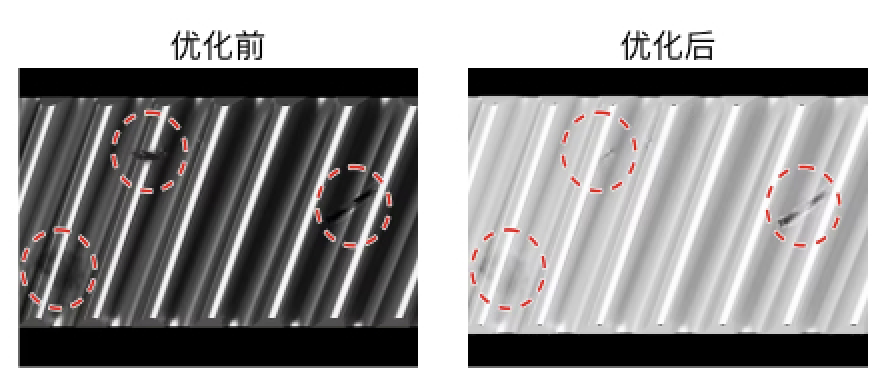

Appearance inspection of battery outer cylinders, etc.

In order to maintain the strength of battery cells and modules, the detection of dents and defects in the outer cylinder is an important inspection process. It is difficult to distinguish and detect undesirable areas such as uneven shading such as minor dents, scratches, and slight stains on the metal surface. The specular reflection mode enables stable detection of only detection targets such as dents or scratches.