ChancePool Automation vision system paired with industrial robot solutions. Robot vision is a robot's ability to perceive and understand the environment based on computer vision technology. It uses cameras, sensors and image processing algorithms to enable robots to acquire, interpret and utilize visual information. This includes tasks such as object detection, tracking, identification, navigation and manipulation. Robot vision has wide applications in manufacturing, logistics, medical care, etc. It improves the autonomy and adaptability of robots, enabling them to better interact with complex environments, perform various tasks, and provide higher levels of automation and intelligence.

------------------------------------------------

Brand:ChancePool

Product Origin:China

Shipping Port:Shanghai

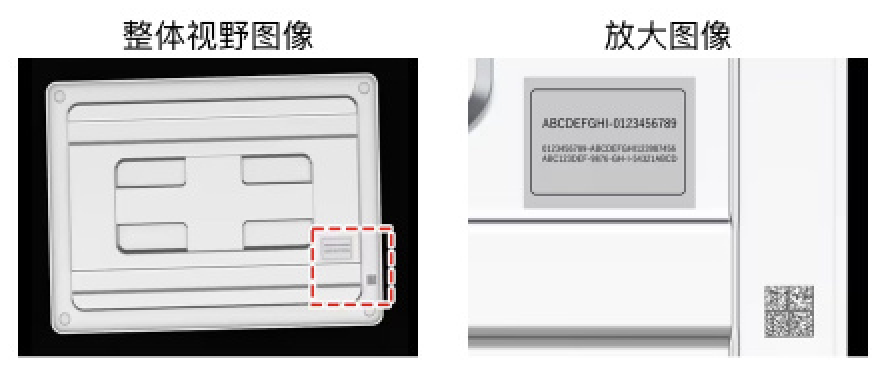

Grab and place

ChancePool Automation's vision system supports various brands of robots and can be easily connected to them. Therefore, the man-hours required for startup can be significantly reduced.

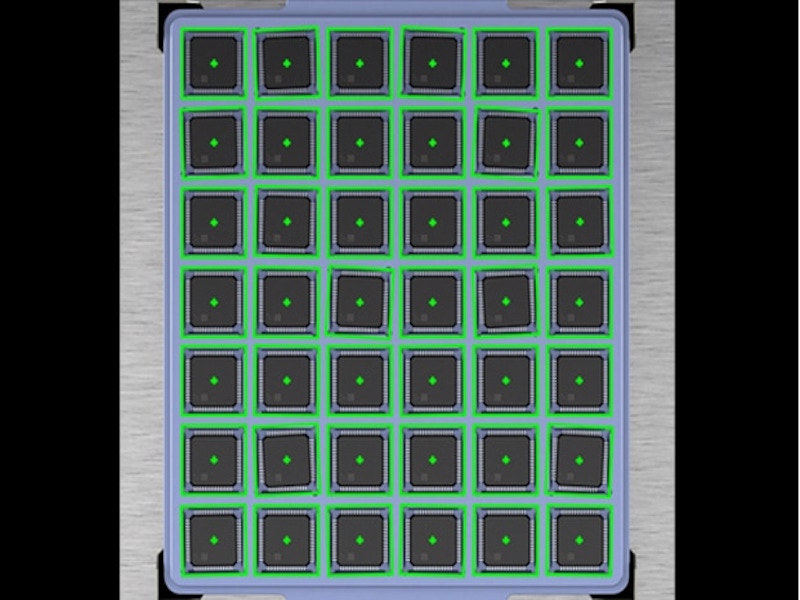

Picking bulk workpieces

Since 4 cameras can generate images without blind spots, the newly developed 3D inspection can quickly provide high-quality inspection results. It is not easily affected by the position or orientation of the workpiece and can achieve stable detection.

Snack packing robot positioning

Snack packaging is a typical process that is mostly done manually. With the introduction of vision systems and robots, automated production has further developed.

Robotic picking of batteries

Robot vision is widely used to advance on-site automation and improve efficiency.

The ChancePool Automation robot vision system can be easily connected to robots from various manufacturers to achieve high-precision picking and placement. Efficiency can be further improved by combining high-pixel cameras with detection such as OCR or QR code reading.